Wood grain treatment of aluminum alloy surface

2019-02-14

The imitation wood grain treatment on the aluminum alloy surface of the building is developed with the demand for the colorful decoration of the building decoration. It is mechanically or chemically applied to give the aluminum alloy surface a woody feel, so that the aluminum alloy has both the characteristics of the metal and the appearance of wood. At present, China's urban and rural areas widely use aluminum alloy to decorate the interior and exterior of the building. The appearance is mainly white, brown and black, which is inconsistent with the doors and windows and furniture of wooden structure. Through the treatment, the grain pattern of the wood grain is formed on the surface of the aluminum and then the coloring is performed to make the plane color light, the color of the line groove is deep, the light and dark are distinct and the appearance is consistent with the wood.

The wood grain processing method for the surface of the aluminum alloy for construction may be a mechanical method, a printing method, a lamination method or an electrolysis method. The mechanical method, the printing method and the lamination method may be generally referred to as a physical method. The electrolysis method is an electrochemical method.

Electrochemical imitation wood grain treatment Japan's Shibata first applied for a patent for chemically etching architectural aluminum to obtain wood grain. Laterly, Kawabata applied for the relevant patents and introduced the mechanism and process of wood grain formation. Japan is now used for industrial production. Researching on aluminum alloy imitation wood grain finishing has been discussed in China, but it has not been applied to production. In order to adapt to the development of China's national economy, this new process has been localized as soon as possible and we have conducted preliminary research on this.

1. Process flow

The experimental aluminum alloy is 6063 aluminum profile, namely A1, Mg, Si alloy. The drugs used are analytically pure reagents. The instruments used mainly including DC stabilized power supplies and AC voltage regulators. The process of aluminum alloy imitation wood grain electrolytic finishing is as follows:

Chemical degreasing → weak etching → wood grain electrolysis → anodizing → coloring → blocking.

Chemical degreasing and weak etching are conventional pretreatments for aluminum alloys.

2. Wood grain electrolysis

Electrolysis can use AC power. Compared with DC power, AC power can improve work efficiency. Because two samples of the same size can be processed at the same time, the AC electrolysis equipment is simple, and only a certain power AC voltage regulator can be used. The wood grain electrolyte is generally composed of an inorganic acid or an organic acid and an alkali metal salt thereof. The boric acid-citric acid system is studied herein.

1) Boric acid

Under the premise of other conditions, the content of boric acid in the electrolyte was changed. It was found that when boric acid was not added, the aluminum alloy was easily corroded and the electrolyte was unstable. With the increase of boric acid content in the solution, the streaks formed on the surface of the aluminum alloy. The spacing is uniform, the thickness is uniform and the pH of the solution is stable. However, when the boric acid content is too high, the streaks are formed less and the marks are thicker.

In the electrolysis process, boric acid is the main component forming a barrier layer, which forms a highly resistive mixed colloidal compound with "Al" and covers the surface of the aluminum substrate to form a barrier layer. The barrier layer is formed alternately with dissolution during electrolysis. Thus, in the thinner portion of the barrier layer, the current density is too high, causing the aluminum matrix to be partially dissolved, and a large amount of gas is generated, and the trajectory of the gas rise accelerates the dissolution of the barrier layer and oxidizes the aluminum to form streaks. In addition, boric acid is a weak acid and hydrolysis can occur in an aqueous solution:

H2BO2 ten H2O → H + ten B (OH) 4-. Therefore, boric acid has a buffering effect on the electrolyte, so that the pH value of the solution is stable, the boric acid content is too low and the buffering effect is not obvious. The content of boric acid is preferably controlled at 11 to 15 g/l.

2) Citric acid

When the citric acid content is too low, the aluminum matrix is easily corroded; the citric acid content is too high. The formed wood grain has a large pitch and the grain is shallow and fine. Citric acid also has the function of forming a barrier film to assist in forming the barrier film. Citric acid and boric acid cannot replace each other and are indispensable. The citric acid content is preferably controlled at 20 to 25 g/l.

3) Etchant

When no etchant is added to the electrolyte, wood grain cannot be obtained. It has been found through experiments that Cl- has a good etching effect. As the Cl- content increases, the etching speed increases and the grain pattern is uniform. When the Cl- content is too high, the etching speed is too fast and the surface of the substrate is too dense. The NaCl content can be controlled in the range of 4 to 7 g/l.

The etchant has the function of dissolving the film, so that the thinner portion of the barrier layer is preferentially dissolved and the substrate is partially exposed. The current density of the portion is large, a large amount of gas is generated and the gas rises along the trajectory under the action of the gas and the etchant. The barrier layer dissolves and gradually forms stripes. When the etchant content is too high, most of the barrier film is dissolved, so that the formed stripes are dense and fine.

The optimum content of the etchant varies with the content of boric acid and citric acid. In general, when the content of boric acid and citric acid is high, the etchant content is correspondingly low. This is because boric acid and lemon have a film-forming action, the etchant has a film-dissolving effect and the two are a contradictory unity.

4) PH value

The pH value has a great influence on wood grain electrolysis. The PH value is low and the etching speed is fast. When the etchant content is too high, the stripe is dense and fine. The high PH value is similar to the etchant content. When the pH value is too high, no wood grain is formed. In order to make the wood grain uniform and the spacing is moderate, the pH of the electrolyte should be controlled at 2.2 to 2.4.

5) Temperature

When the temperature is too low, it is not easy to form wood grain. When the temperature rises, the film speed is fast, and the formed stripes gradually approach normal. In general, the temperature is higher - some, the wood grain electrolysis effect is better. However, from the perspective of energy conservation, the temperature should not be too high, preferably at 20 to 35 °C.

6) Electrolysis time

Electrolysis time can affect the depth and continuity of the stripes while keeping other conditions constant. The time is too short, the wood grain is not obvious, the time is too long, the surface of the substrate is too corroded, and the stripes are not realistic. The electrolysis time varies depending on the composition of the electrolyte, the temperature and the pH value, the etchant content is high, the boric acid and citric acid content are low, the pH value is low, and the temperature is high, the electrolysis time needs to be shorter. On the contrary, the electrolysis time needs to be prolonged.

After the above analysis and discussion, the effects of electrolyte composition and process conditions on imitation wood grain electrolysis were clarified. On the 6063 aluminum alloy, in order to obtain a more realistic wood grain surface, the following electrolyte composition and process conditions can be used.

Boric acid 11~15g/l

Citric acid 20~25g/l

Sodium chloride 4~7g/l

Current density 1~3A/dm3

PH value 2.2~2.4

Temperature 20~35°C

Time 5~8min

3. Film removal

In the wood grain electrolysis process, a barrier film is formed on the surface of the aluminum alloy substrate to form a black substance on the wood grain trace. If the anodic oxidation is directly carried out without removing the black substance, the oxidizing solution will be contaminated and eventually the coloring uniformity and durability will be directly affected.

The membrane solution is usually a sodium carbonate solution and the effects of the membrane are as follows:

1) Effect of sodium carbonate

The sodium carbonate content is too low and the film removal rate is slow. As the content thereof increases, the film removal speed increases. However, when the content is too high, the reaction is too intense, the barrier film is easily dissolved together and the solution is liable to cause precipitation. The sodium carbonate content is preferably 50 to 60 g/l.

2) The effect of temperature

Temperature is an important factor affecting the speed of film removal. If the temperature is too low, the film removal speed is too slow; if the temperature is too high, the reaction is too intense and difficult to control. In order to obtain a good film removal effect, the temperature is controlled at 50 to 65 °C.

3) Effect of film removal time

The film removal time varies depending on the sodium carbonate content and temperature. If the sodium carbonate content and temperature are high, the film removal time needs to be shorter, and the film removal time should be longer. When the film removal time is insufficient, the black material cannot be completely removed; if the time is too long, the aluminum alloy substrate is easily corroded. The film removal time is preferably 1 to 2 minutes.

The optimum composition and process conditions of the membrane removal solution are: sodium carbonate 50-60 g/l, temperature 50-65 ° C, time 1-2 min.

4. Anodizing

The anodizing process can adopt the conventional sulfuric acid oxidation process. The composition and process conditions are: sulfuric acid 140-160g/l, A13+0.11-0.5g/l, temperature 20-25 °C, current density (DA) 1.1-1.5A/ Dm2, the cathode is a lead plate.

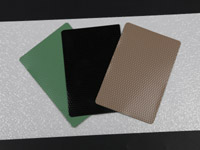

5. Electrolytic coloring

Through the above treatment, only the same surface as the wood grain rib is obtained and it is necessary to undergo a coloring treatment to give it a woody feeling. It has been confirmed by experiments that the electrolytic coloring effect is good and various electrolytic coloring liquids are used to obtain various wood colors.

The following imitation electrolysis process can be used to obtain the chestnut-like color (chocolate color), and the difference in the groove and the flatness of the plane is obvious.

Nickel sulfate 40g/l, sulfuric acid steel 4g/l, boric acid 25g/l, pH value 4.0, current density 0.5A/dm2, temperature at room temperature, time 5min, the plate is stainless steel. The imitation eucalyptus color (yellow), imitation bronze color, etc. can also be obtained by changing the electrolyte composition.

6. Closed treatment

In order to improve the corrosion resistance of the colored film, to prevent contamination, and to enhance the stability, light resistance and weather resistance of the film, it is necessary to carry out the sealing treatment as the last step of the imitation wood grain electrolytic finishing.

The process of the closed treatment is: soaking in distilled water of 95 to 100 ° C for 20 to 30 minutes.

In conclusion

In this paper, a preliminary study on aluminum alloy wood grain electrorefining is carried out. The boric acid-citric acid system is used for wood grain alternating electrolysis, then the film is removed in sodium carbonate aqueous solution, further anodized in sulfuric acid aqueous solution, and different electrolysis coloring process is adopted. Coloring, and finally sealing treatment in boiling water can obtain a realistic surface like chestnut wood, eucalyptus, etc., the color film is stable and the weather resistance is good.

(Chat Online)

(Chat Online)