The performance characteristics of composite wood aluminum

2015-05-11

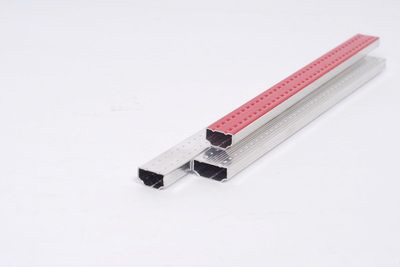

1. Composite wood aluminum structure design

Outdoor part of aluminum alloy, the member is a nylon insulation strip and chip aluminum composite wood profiles indoor section, significantly reduces the thermal conduction window profiles section.

2. Good noise performance overall window

About 10-15 dB lower noise than aluminum doors and windows broken insulation.

3. Excellent insulation properties

Without special treatment standard conventional 22mm hollow glass window of K <2.42W / (m2.K) filled with inert gas K <2.0W / (m2.K).

4. Anti-aging ability

Indoor simulation wood layer having high resistance to solvents and anti-ultraviolet function, anti-CP grade Astons swab repeatedly wiping more than fifty times.

5. Excellent processing performance

This product is a composite wood and aluminum combined to form one organic profile processing, without having to add wooden equipment, paint production line and research problems such as moisture content of wood to produce high-grade aluminum composite wood doors and windows, but no cracking, mildew ants termite problems and other quality problems.

6. Color and colorful materials

Aluminum composite wood composite wood interior portion is formed by high corrosion resistance composite film grain simulation technology to achieve high-grade natural wood decorative effect and basically maintenance-free, meet people close to nature to enjoy.

7. Green

Aluminum wood polymer composite materials used in halogen-free polymers, advanced wood flour, high-precision aluminum, plastic injection PU resin, pass bar with Nylon66 + glass fiber and other materials, molding of the extruded product after treatment using The raw materials are all green non-volatile, non-radioactive material, no benzene, ammonia and dioxins and other toxic and harmful gases at high temperatures.

(Chat Online)

(Chat Online)