Five kinds of aluminum surface treatment methods

2015-07-20

What are the five major surface treatment of aluminum?

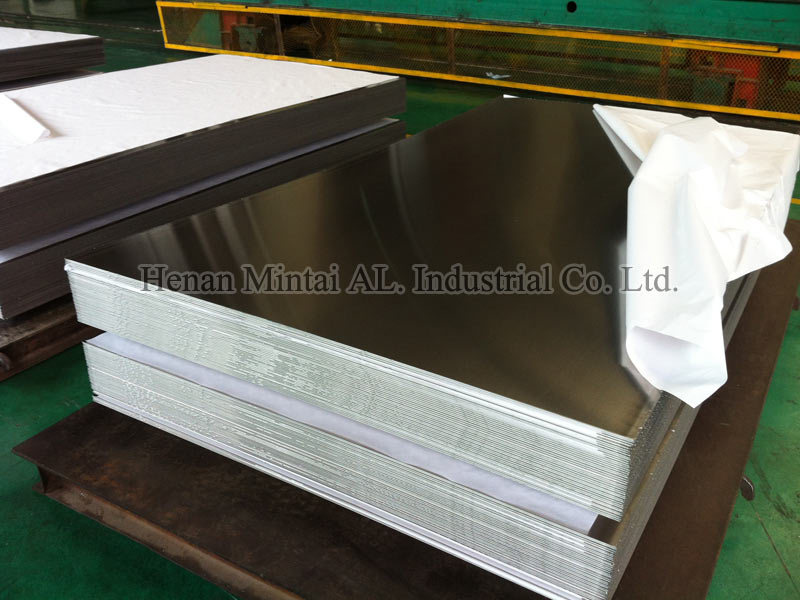

Aluminum is now special widely used in the construction industry, especially decoration building materials. Aluminum beauty is concerned. So more manufacturers now are more concerned about aluminum surface aesthetics.

1. electrophoretic coating

This process is now used by Japan, after such processing, aluminum plates smooth side to the surface, corrosion resistance is enhanced.

2. electrostatic powder spraying

Main feature is to enhance the corrosion resistance of aluminum, acid, alkali and salt, the plates were better than the coloring of aluminum profiles.

3. scrub the fabric

Pattern aluminium is very light in itself, but in our lives to some interference may occur in the context of the highlights, scrub use this shortcoming can be a good customer service, its surface smooth like silk, liked by a lot of people.

4. surface treatment of tones

Previously the traditional color of aluminum already cannot meet the needs of designers, in order to make better use in a variety of colors, make aluminum color more perfect, the most important point is that need to be polished after the oxidation process, the effect is the best.

5. the surface of plasma enhance electrochemical ceramic

This is the use of advanced science and technology. After this treatment of aluminum sheet quality is outstanding, although cost is high, but a penny stock. This is the most important aluminium plates can also be used for a range of color.

If you want to know more about it,please go on visiting our website.

(Chat Online)

(Chat Online)