Aluminum plates alloy 1000-8000 series

2019-01-03

The alloy aluminum plate is added with various alloying elements during the processing of the aluminum plate (the main alloying elements are copper, silicon, magnesium, zinc, manganese, and the secondary alloying elements are nickel, iron, titanium, chromium, lithium, etc.) to improve the mechanics of the aluminum plate performance and chemical indicators.

1. The alloy aluminum plate can be divided into 2××× series as aluminum-copper alloy aluminum plate (Al--Cu) according to the main alloying elements. 3××× is aluminum-manganese alloy aluminum plate (Al--Mn). 4××× series It is an aluminum-silicon alloy aluminum plate (Al--Si). 5××× system is an aluminum-magnesium alloy aluminum plate (Al--Mg). 6××× system is an aluminum-magnesium-silicon alloy aluminum plate (AL--Mg--Si). 7××× is an aluminum-zinc alloy aluminum plate [AL--Zn--Mg--(Cu)].

2. Alloy aluminum plate can be divided into binary alloy aluminum plate, ternary alloy aluminum plate, quaternary alloy aluminum plate and multi-alloy aluminum plate according to element unit.

3. The alloy aluminum plate can be divided into heat-resistant strengthened alloy aluminum plate and non-heat-treated strengthened alloy aluminum plate according to the heat treatment. The alloy aluminum plate cannot be strengthened, and only cold working can be strengthened. The heat treatment can not be obviously strengthened.

Alloy aluminum plate manufacturers detailed introduction

2××× series alloy aluminum plate

2××× series alloy aluminum plate: representative 2A16 (LY16), 2A06 (LY6). 2××× series aluminum plate is characterized by high hardness, among which the highest copper content is about 3-5%. 2×× × series aluminum plates are aerospace aluminum materials, which are not commonly used in conventional industries. China currently produces 2××× series aluminum plates with fewer manufacturers. The quality cannot be compared with foreign countries. The imported aluminum plates are mainly produced by Korea and Germany. Provided by enterprises. With the development of China's aerospace industry, the 2××× series of aluminum sheet production technology will be further improved.

3××× series alloy aluminum plate

3××× series alloy aluminum plate: representing 3003 aluminum plate, 3004 aluminum plate and 3A21 aluminum plate. It can also be called rust-proof aluminum plate. China 3××× series aluminum plate production process is excellent. 3××× series aluminum plate is made of manganese element, the main component. The content is between 1.0-1.5%. It is a series with better anti-rust function. The conventional application is in the humid environment such as air conditioner, refrigerator and car bottom. The price is higher than 1××× series. It is the commonly used alloy series.

4××× series alloy aluminum plate

4××× series alloy aluminum plate: The representative is 4A01. It belongs to series with high silicon content. Usually silicon content is between 4.5-6.0%. It belongs to building materials, mechanical parts, forging materials, welding materials and low melting point, resistant. Corrosive product description: It has the characteristics of heat resistance and wear resistance.

5××× series alloy aluminum plate

5××× series alloy aluminum plate: representing 5052 aluminum plate, 5005 aluminum plate, 5083 aluminum plate, 5A05 aluminum plate series. 5××× series aluminum plate belongs to the more common alloy aluminum plate series. The main element is magnesium and the magnesium content is 3-5%. It can also be called aluminum-magnesium alloy. The main features are low density, high tensile strength and high elongation. The weight of aluminum-magnesium alloy is lower than other series under the same area. Therefore, it is commonly used in aviation, such as aircraft fuel tank. The application in the conventional industry is also extensive. The processing technology is continuous casting and rolling, which belongs to the hot-rolled aluminum plate series, so it can be used for oxidative deep processing. In China, the 5××× series aluminum plate is one of the more mature aluminum plate series.

6××× series alloy aluminum plate

6××× series alloy aluminum plate: representing 6061 aluminum plate and 6063 aluminum plate. It mainly contains two elements of magnesium and silicon, so it concentrates on the advantages of 4××× series and 5××× series. 6061 is a cold-processed aluminum forged product. It is suitable for applications with high corrosive and oxidizing requirements. It has good workability, excellent interface characteristics, easy coating and good processability. It can be used on low pressure weapons and aircraft joints.

General features of 6061: excellent interface characteristics, easy coating, high strength, good workability and strong corrosion resistance. Typical uses: aircraft parts, camera parts, couplers, marine parts and hardware, electronic parts and connectors, decoration Use or a variety of hardware, hinged heads, magnetic heads, brake pistons, water pistons, electrical accessories, valves and valve parts.

7××× series alloy aluminum plate

7××× series alloy aluminum plate: representating 7075. It mainly contains zinc element and also belongs to aviation series, which is aluminum magnesium zinc copper alloy, heat treatable alloy. It belongs to super hard aluminum alloy with good wear resistance. 7075 aluminum plate is eliminated. The stress will not be deformed or warped after processing. All the ultra-thick and ultra-thick 7075 aluminum plates are all ultrasonically detected to ensure no blisters and impurities. The 7075 aluminum plate has high thermal conductivity, which can shorten the molding time and improve work efficiency. Main features is high hardness and high strength aluminum alloy. It is commonly used in the manufacture of aircraft.

Related technical standards

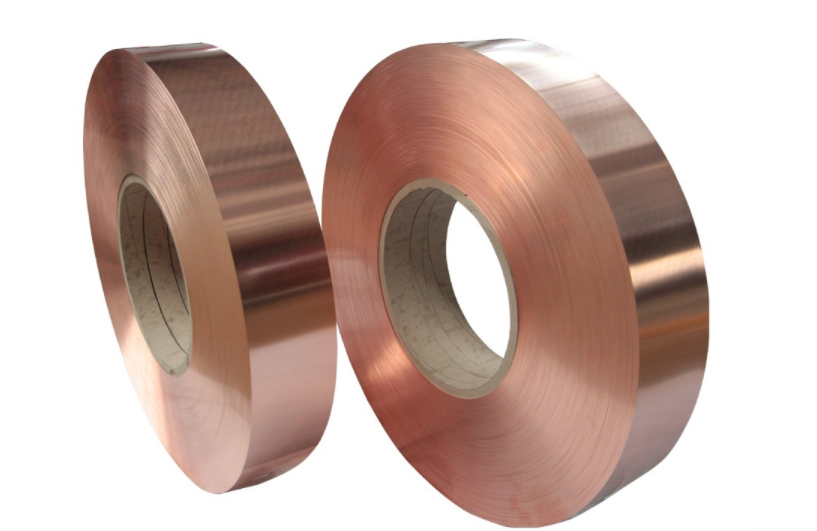

Aluminum plate with national standard (GB/T 3880-2006) is suitable for the uniform standard of aluminum alloy strip material.

(Chat Online)

(Chat Online)