Aluminum-Henan Mintai Aluminum

2015-09-04

Aluminum-Henan Mintai Aluminum

Aluminum (also known as aluminium) is the most abundant metal element in the earth's crust. And it's a good thing too, because we use a lot of it. About 41 million tons are smelted each year and employed in a wide arrange of applications. From auto bodies to beer cans, and from electrical cables to aircraft skins,from food packaging to medicine pills,from daily pots to ads signs, aluminum is a very big part of our everyday lives.

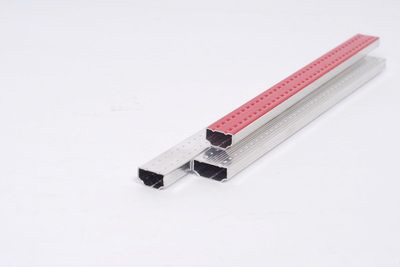

►Aluminium profile

►Aluminium Machine

►Aluminum Alloys

►About us

♦Aluminum Profile

Characteristics:

Aluminum is a lightweight, highly conductive, reflective and non-toxic metal that can be easily machined. The metal's durability and numerous advantageous properties makes it an ideal material for many industrial applications.

History:

Aluminum compounds were used by ancient Egyptians as dyes, cosmetics and medicines, but it was not until 5000 years later that humans discovered how to smelt pure metallic aluminum. Not surprisingly, the development of methods to produce aluminum metal coincided with the advent of electricity in the 19th century, as aluminum smelting requires significant amounts of electricity.

A major breakthrough in aluminum production came in 1886 when Charles Martin Hall discovered that aluminum could be produced using electrolytic reduction. Until that time, aluminum had been more rare and more expensive than gold.

However, within two years of Hall's discovery, aluminum companies were being established in Europe and America.

During the 20th century, aluminum demand grew substantially, particularly in the transportation and packaging industries. Although production techniques have not changed substantially, they have become notably more efficient. Over the past 100 years, the amount of energy consumed to produce one unit of aluminum has decreased 70%.

Applications:

Aluminum's applications are too numerous to list, and because of the metal's special properties researchers are finding new applications on a regular basis. Generally speaking, aluminum and its many alloys are used in three major industries; transportation, packaging and construction.

Aluminum, in a variety of forms and alloys, is critical to the structural components (frames and bodies) of aircraft, automobiles, trains and boats. As much as 70% of some commercial aircrafts consist of aluminum alloys (measured by weight). Whether the part requires stress or corrosion resistance, or tolerance to high temperatures, the type of alloy used is dependent upon the requirements for each component part.

About 20% of all aluminum produced is used in packaging materials. Aluminum foil is a suitable packaging material for food because of it is non-toxic, whereas it is also a suitable sealant for chemical products because of its low reactivity and is impermeable to light, water and oxygen. In the US alone, about 100 billion aluminum cans are shipped every year. Over half of these are eventually recycled.

Because of its durability and resistance to corrosion, about 15% of aluminum produced each year is used in construction applications. This includes windows and door-frames; roofing, siding and structural framing, as well as gutters, shutters and garage doors.

Aluminum's electrical conductivity also allows it to be employed in long distance conductor lines. Reinforced with steel, aluminum alloys are more cost efficient than copper and reduce sagging due to their light weight.

Other applications for aluminum include shells and heat sinks for consumer electronics, street lighting poles, oilrig top-structures, aluminum coated windows, cooking utensils, baseball bats and reflective safety devices.

♦Aluminum Machine

•Aluminium Hot Rolling Mill

The hot rolling mill with single-stand and double–coiler can roll the cast slab of thickness 300~500mm down to the strip and sheet of final thickness 5mm after several passes. The mill housings with large hardness can efficiently avoid impact and increase the rolling stability. The reduction of big pass is fully taken into consideration in the design of roll diameter. The improvement of roll wiper can satisfy the requirements of the roll surface quality to ensure the optimum strip surface quality. The screw down adopts electric screw down and hydraulic AGC mode which can integrate the roughly and finely adjustment of roll gap adjustment. The electric control system uses the programmable controller and field network technology with advanced configuration and high automation.

•Aluminum Cold Rolling Mill

Cold rolling mill can roll the aluminium cast coils or hot rolled coils of thickness 6~8mm down to the finished products of thickness 2~0.05mm after several passes. Cold rolling mill is equipped with advanced hydraulic automatic gauge control (AGC) system and perfect advanced automatic flatness control (AFC) system which can provide many kinds of control methods such as roll tilting, positive and negative work roll bending and roll cooling in segments. According to the customer need, the mill can be equipped with state-of-art AFC system to roll out the optimized flat products in terms of thickness and flatness precision. All the DC motors can be supplied power by the advanced full digital thyristor due to the high automation of the mill. PLC (programmable controller) is used to carry out the advanced electric control such as digital logical calculation, data set-up, automatical control etc. At the same time, the mill is also equipped with various perfect accessory systems such as advanced plate filter, safe and liableCO2 automatical fire extinguishing system, lubricating system, dry air blow off device, fume exhaust device, and accurate strip deviation detecting system etc. to provide liable guarantee for producing good quality products.

•Aluminium Foil Mill

Aluminium Foil Mill: The aluminium foil mills are all in good operating conditions. The performance targets of the standard type ф260/700×1600mm aluminium foil roughing and finishing mill have reached international advanced level in quality and performance. The finished products thickness of finishing mill is up to 0.006mm.In 2006. developed a 2000mm wide aluminium foil mill and got through the test run successfully in 2008 marking that the designing and manufacturing technology of aluminium foil mill ,It has approached the international advanced level.

♦Aluminum Alloys

•1xxx:Controlled unalloyed (pure) composition,used primarily in theelectrical and chemical industries

•2xxx:Alloys in which copper is the principal alloying element,although other elements,notably magnesium,may be specified. 2xxx- series alloys are widely used in aircraft where their high strength(yield strengths as high as 455 MPa,or 66 ksi) is valued.

•3xxx:Alloys in which manganese is the principal alloying element,used as general purpose alloys for architectural applications and vari-ous products.

•4xxx:Alloys in which silicon is the principal alloying element,used inwelding rods and brazing sheet

•5xxx:Alloys in which magnesium is the principal alloying element,used in boat hulls,gangplanks,and other products exposed to marineenvironments

•6xxx:Alloys in which magnesium and silicon are the principal alloying elements,commonly used for architectural extrusions and auto-motive components

•7xxx:Alloys in which zinc is the principal alloying element (althoughother elements,such as copper,magnesium,chromium,and zirconium,may be specified),

used in aircraft structural components and otherhighstrength applications. The 7xxxseries are the strongest aluminumalloys,with yield strengths ≥500 MPa

(≥73 ksi) possible.

•8xxx:Alloys characterizing miscellaneous compositions. The 8xxxseriesalloys may contain appreciable amounts of tin,lithium,and/or iron.

•9xxx:Reserved for future use

Common Aluminum Alloys and their Applications

|

Aluminum Alloy and Temper

|

Typical Applications

|

1100-O

1100-H14 |

Commercially pure aluminum resistant to chemical attack & weathering, low cost, ductile for deep drawing & easy to weld, used in chemical equipment, fan blades, sheet metal work. |

2014-O

2014-T4, T451

2014-T6, T651

|

Truck Frames, aircraft structures, automotive parts, cylinders &pistons, machine parts, structural applications |

| 2017-T4, T451 |

Fasteners, fittings |

2024-O

2024-T3, T4

2024 -T351

Alclad |

High strength structural applications, excellent machinability in T-temper, fair workability &corrosion resistance, alclad combines high strength and corrosion resistance, used in truck wheels, aircraft structures, automotive parts, fasteners, recreation equipment, screws & rivets |

3003-O

3003-H12

3003-H14

3003-H16 |

Most popular general-purpose alloy, stronger than 1100 with same good formability & weldability, used in cooking utensils, chemical equipment, pressure vessels, sheet metal work, builder's hardware, storage tanks, trucks & trailers, architectural |

3004-O

3004-H38 |

Sheet metal work, storage tanks, agricultural applications, building products, containers, electrical applications, furniture, trucks &trailers |

3105-O

3150-H14

3150-H18

3150-H25 |

Siding, sheet metal work, automotive parts, building products, electronics, furniture, trucks & trailers |

3105-O

3150-H14

3150-H18

3150-H25 |

Siding, sheet metal work, automotive parts, building products, electronics, furniture, trucks & trailers |

| 5005-H34 |

Appliances, utensils, architectural, electrical conductors, general sheet metal, hardware, marine applications |

5052-O

5052-H112

5052-H32

5052-H34 |

Stronger than 3003, readily formable, good weldability & resistance to corrosion, used in sheet metal work, hydraulic tube, appliances, pressure vessels, hardware signs, marine applications, trucks |

6061-O

6061-T4

6061-T6, T651 |

Good formability, weldability, corrosion resistance, & strength in the T-tempers, good general-purpose alloy used for a broad range of structural applications & welded assemblies, pipeline, marine applications, furniture, agricultural applications, aircraft's, architectural, building products, chemical equipment, electrical and electronic parts, fasteners, general sheet metal, recreation equipment, storage tanks |

6063-T5

6063-T6 |

Pipe railing, furniture, architectural extrusions, marine applications, truck & trailer, recreation equipment, building products, electrical and electronic parts |

| 7050-T7651 |

High strength alloy in aircraft & structures, recreation equipment

|

♦

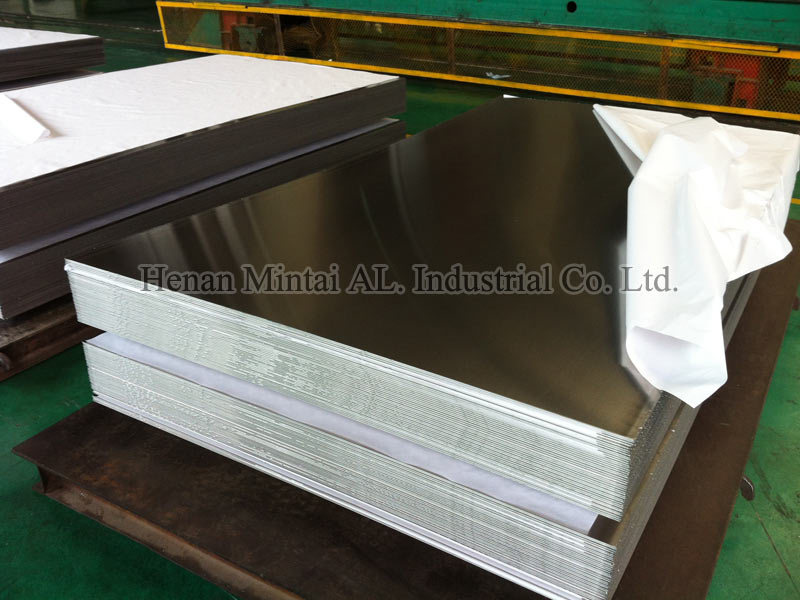

About us

As a professional manufacturer and supplier of aluminum products based in China, we can provide

aluminum sheet, aluminum circle,aluminum foils,5 bar aluminum tread plate, aluminum strip, aluminium slit coil, anodising aluminum sheet, diamond aluminum tread plate, and more. Whenever you have a need for any of our products, please feel free to contact us .

Email:sales@mintaialuminum.com

Tel:+86 15838001176

Website:www.mintaialuminum.com

(Chat Online)

(Chat Online)