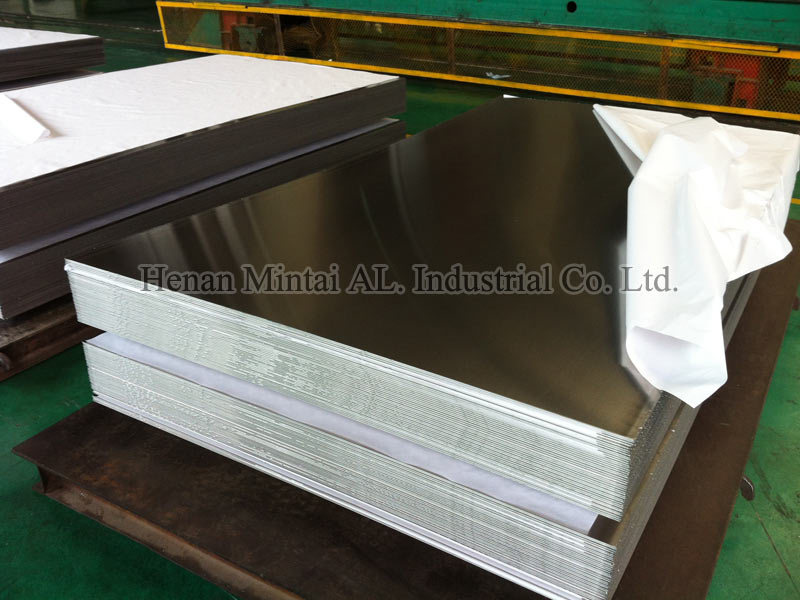

5A02 Aluminum Features and Applications

2015-06-09

5A02 Al-Mg system for anti-rust aluminum alloy, non-heat strengthened. Low magnesium content of the alloy, its high plasticity, forming the model, but lower strength, and higher than the strength 3A21 alloy. Cold deformation can improve their strength, and ductility decreases. Good corrosion resistance of the alloy, suitable for use in a marine environment. Alloy welding good. Its mach inability in the annealed condition is poor; semi-cold cherry states can improve mach inability.

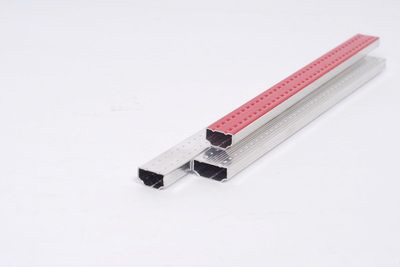

5A02 alloy is suitable for a high degree of plasticity process requirements and good corrosion resistance of welded structures and containers, if wanted, gasoline and lubricants catheters, nails, flanges, and parts, ships, interior trim light duty vehicles, etc. pickles or rod used as a counsel.

Mechanical properties:

Tensile strength σb (MPa): ≤147

Elongation δ10 (%): ≥14

Note: checkered mechanical properties at room temperature

● Heat treatment:

1) Homogenization: Heat 440 ℃; holding 12 ~ 14h; air cooling.

2) Rapid thermal annealing: heating 350 ~ 410 ℃; holding time 30 ~ 120min; air or water.

3) High temperature annealing: heating 350 ~ 420 ℃; finished thickness ≥6mm or <6mm, the holding time of 2 ~ 10min or 10 ~ 30min; air cooling.

4) Low-temperature annealing: heating 250 ~ 300 ℃ or 150 ~ 180 ℃; holding time of 1 ~ 2h, air-cooled state: aluminum and aluminum checkered plate (O state).

(Chat Online)

(Chat Online)