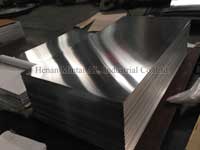

2a16 Aluminum Alloy

2015-04-22

Material Name: 2a16 aluminum

Standard: GB / T3190-1996 main features and applications: This is a hard heat-resistant aluminum, its features are: strength at room temperature is not too high, but at high temperatures there is a high creep strength alloys. There are hot under the strength of the plastic, no squeezing effect that can handle strengthened, spot, seam. Welding performance is good, the tendency to form cracks less significant; Weld tightness is still good, low weld corrosion stability; Package corrosion stability of the aluminum plate is still good; semi-finished extruded corrosion resistance is not high, to prevent corrosion, should be anodized or painted protection. It still has good machinability. Mainly used parts at 250-350 ℃ work, such as bearings to the compressor blades, discs, plates and weldments used for room temperature under high temperature, such as containers, airtight compartment, etc.

Mechanical properties:

Tensile strength σb (MPa)) ≥355

Conditions yield strength σ0.2 (MPa)) ≥235

Sample Size: All Thickness

Note: The vertical pipe at room temperature mechanical properties

● Heat treatment:

1) Homogenization: Heat 515 ~ 530 ℃; holding 12 ~ 16h; furnace cooling.

2) Complete annealing: heating 380 ~ 450 ℃; holding time 30 ~ 120min; air cooling.

3) Rapid thermal annealing: heating 350 ~ 370 ℃; holding time of 30 ~ 120min; air cooling.

4) Quenching and aging: hardening 530 ~ 540 ℃, water cooling; artificial aging (forgings, sheet) 160 ~ 170 ℃, 10 ~ 16h, air-cooled; natural aging at room temperature Anytime.

(Chat Online)

(Chat Online)