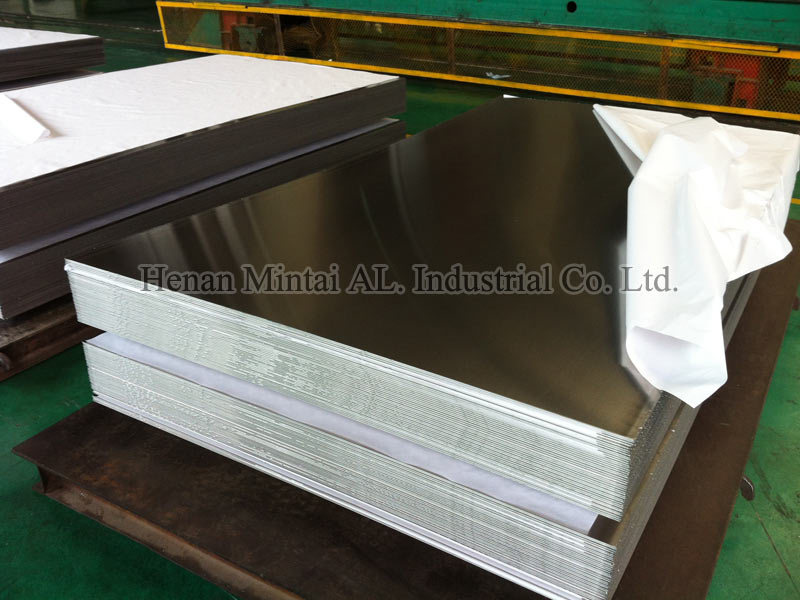

2A11 Aluminum Alloy

2015-04-21

2A11 aluminum Features and Scope:

2A11 aluminum is the first application of a hard aluminum, commonly referred to as a standard hard aluminum, with moderate intensity, at annealing, quenching and thermal state just plasticity is still good, can heat strengthened, used in the quenched and naturally aged condition, the point Welding is good, there is tendency to crack When welding and welding; aging can be cut in the quenched state is still good, bad in the annealed condition.

2A11 aluminum alloy mechanical properties:

Tensile strength σb (MPA): ≥370

Conditions yield strength σ0.2 (MPA): ≥215

Elongation δ5 (%): ≥12

Note: The vertical bar at room temperature mechanical properties

Sample size: bar diameter (square bar, hexagon bar inscribed circle diameter) ≤150

2A11 aluminum heat treatment specifications:

1) Homogenization: Heat 480 ~ 495 ℃; holding 12 ~ 14h; furnace cooling.

2) Complete annealing: heating 390 ~ 430 ℃; holding time 30 ~ 120min; air cooling.

3) Rapid thermal annealing: heating 350 ~ 370 ℃; holding time of 30 ~ 120min; air cooling.

4) Quenching and aging: hardening 495 ~ 510 ℃, water cooling; artificial aging 155 ~ 165 ℃, 6 ~ 10h, air-cooled; natural aging: room 96h.

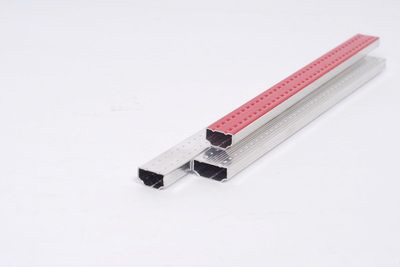

2A11 aluminum Status: aluminum and aluminum alloy extruded bars (≤150mm, H112, T4 state).

(Chat Online)

(Chat Online)