2A10 Aluminum Performance

2015-04-20

● Features and Scope:

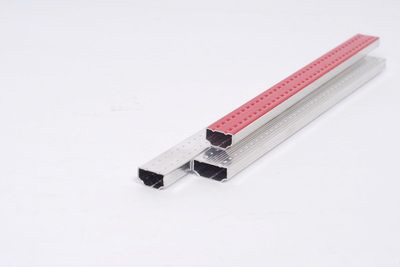

2A10 aluminum alloys are the rivets. High shear strength, annealing, just quenching, aging and thermal state have sufficient plasticity rivet is required; with riveted after quenching and aging, the time limit is not heat-treated after the riveting process. Aluminum 2A10 and 2A11 same weld ability, corrosion stability and 2A01, 2A11 same rivets. Heated above 100 ℃, intergranular corrosion tendencies.

● Mechanical Properties:

Shear strength τ (MPa): ≥245

Note: After the wire solution heat treatment to natural aging state shear stable performance

Sample size: wire diameter ≥8.0

● Heat treatment:

1) Complete annealing: heating 390 ~ 430 ℃; with the effective thickness of different materials, holding time 30 ~ 120min; with 30 ~ 50 ℃ / h speed with furnace cooling to below 300 ℃, and then cooled.

2) Rapid thermal annealing: heating 350 ~ 370 ℃; with the effective thickness of different materials, holding time 30 ~ 120min; air cooling.

3) Quenching and aging: hardening 510 ~ 520 ℃, water cooling; artificially aged 70 ~ 80 ℃, 24h, air-cooled; natural aging room 240h.

Status: rivet aluminum and aluminum alloy wire (≥8.0mm, T4 state).

(Chat Online)

(Chat Online)