5052 Aluminum Plate for Vehicle Mobile Cabin Skin,The Ultra-Wide Aluminum Plate Width Reaches 2600mm

2023-03-03

As a general equipment loading platform, square cabin has strong mobility and environmental adaptability, and gradually enters more application fields. The cabin body adopts a large plate structure, which is made of frame, skin, thermal insulation material and partition thermal bridge by pressing and molding. After continuous development, lightweight square cabins based on aluminum alloy or composite materials have become a new trend.

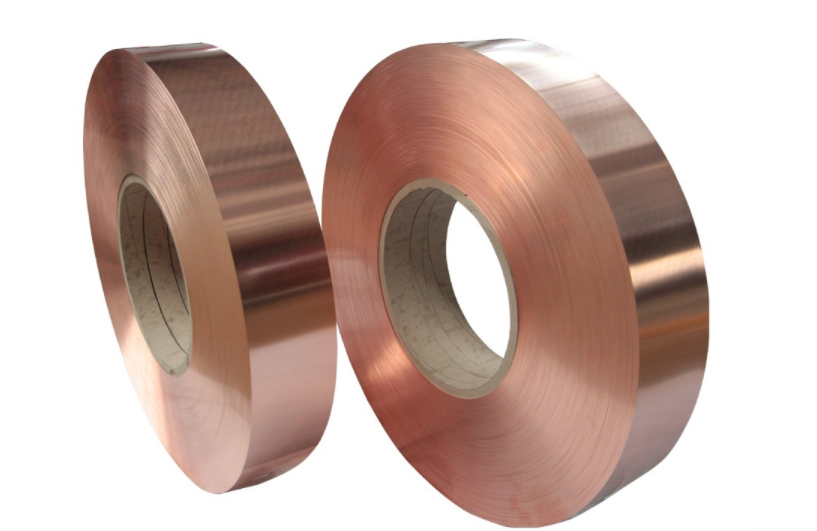

As we all know, aluminum alloy has small density and light weight, and it is increasingly used in the field of lightweight. The skin of the vehicle cabin generally adopts 3003 aluminum plate and 5052 aluminum plate strip, with a thickness of 1.2-3.0mm. The aluminum alloy square cabin skin has excellent workability, good weight reduction effect, excellent sealing, transportation flexibility, and can be applied to the specific needs of different environments, and has been widely used.

The square cabin skin generally adopts wide aluminum alloy plate, and the processing accuracy and manufacturing quality of the material directly affect the comprehensive performance and service life of the cabin. As a large-scale aluminum plate and foil manufacturer, Mintai Aluminum has a history of 25 years, and has become one of the more competitive large-scale comprehensive aluminum processing enterprises in China, with an annual output of 1.3 million tons of various aluminum plate and foil products.

The company has advanced equipment, professional and technical personnel, to achieve customized production. The width of 3003 aluminum plate and 5052 aluminum plate for Mintai aluminum square cabin skin can reach 2600mm, and the performance can be stable and reliable, which meets the user's post-processing requirements.

(Chat Online)

(Chat Online)