Aluminium drill entry sheet is used with double-sided and multilayer circuit boards to meet both the performance and cost requirements for general PCB drilling.

Specification of aluminium drilling entry

THickness:0.14-0.24

Alloy:1100 3003

Temper:H18

Form:Coils Or sheets

Advantages(aluminum drilling entry)

1. Mintai's aluminum sheets can protect the circuit board against scratches and pressing marks.

2. aluminum sheet improves the nicety degree of the drilling position. It makes the drilling have guidance so that the drill works without deflection.

3. aluminum sheets significantly lengthens the life of the drill bit. Its specific alloy composition can keep the cleanness and the cooling of the drill bit. Whats more, it is a good conductor of heat so it prevents overheating of the drill bit and it can avoid the oxidation of the surface.

4.The aluminum drilling entry could be recycled

5.Thickness options available for different applications

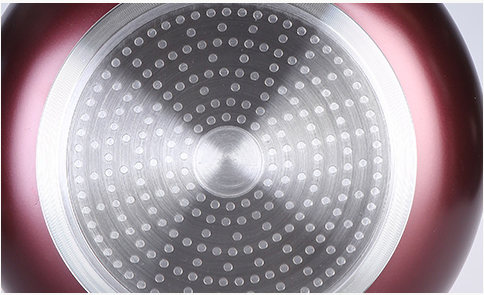

Aluminium sheet in PCB Drilling Process

The first step in the manufacturing PCB (for two layer) is drilling. The CNC drill machines are enormous. Some of the machinces are setup to drill three panels at once and one of the bigger machines (pictured below) could drill six panels of PCBs simultaneously! A layer of aluminum foil sheet is laid down over the board stock to help absorb and distribute heat from the drilling process.

After drilling, the PCB panels have the aluminium foil sheet covering removed and are ran through a machine to remove burs and smooth out any other abraisions that may have happened during the drilling process. This ensures that surface is relatively uniform for the electroless chemical plating process, the next step. The aluminum foil sheet protects the board.

After being drilled, the boards are cleaned.

Mintai Aluminum welcome your inquiry.

(Chat Online)

(Chat Online)